Sheet Metal Stampings

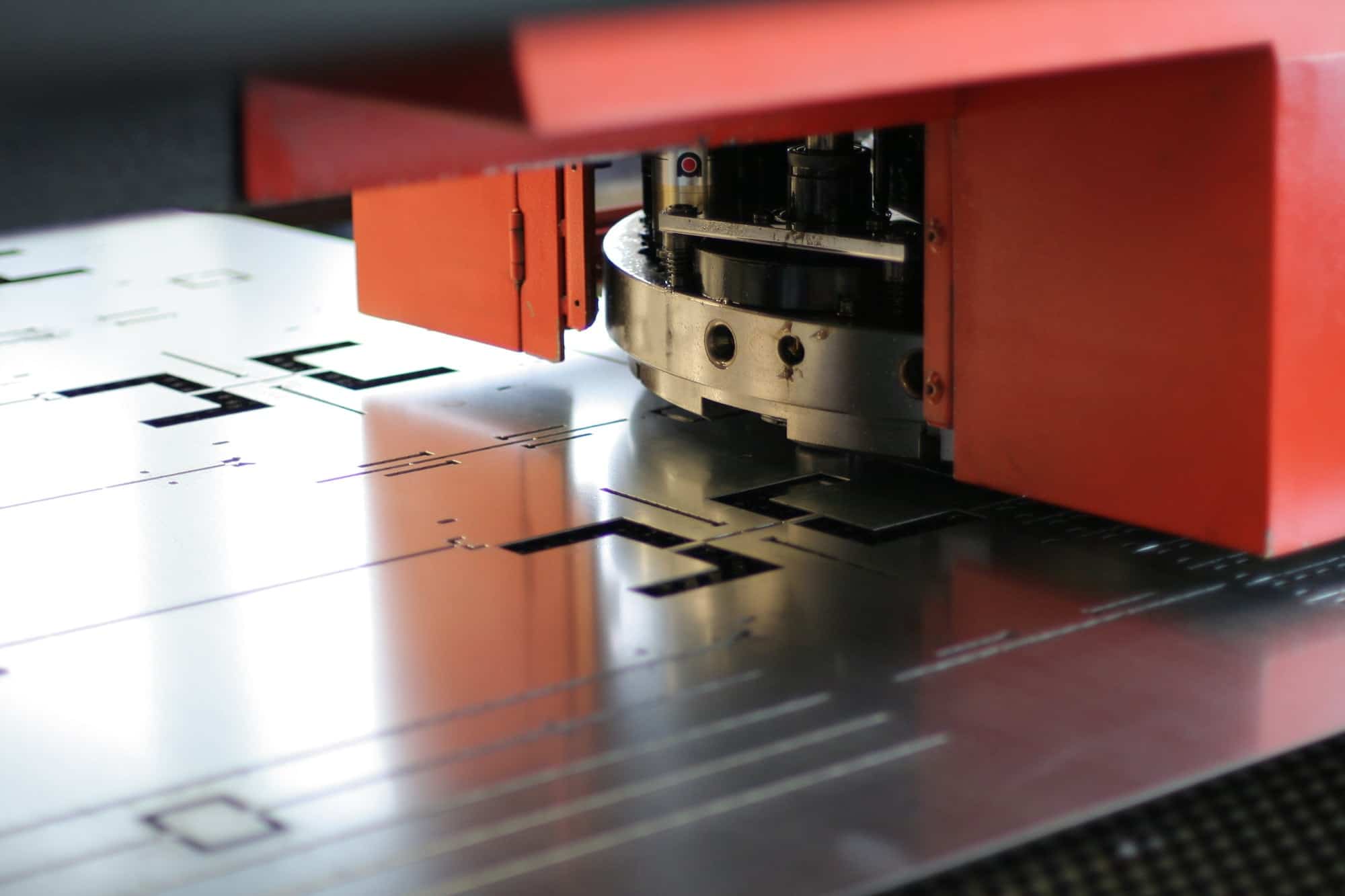

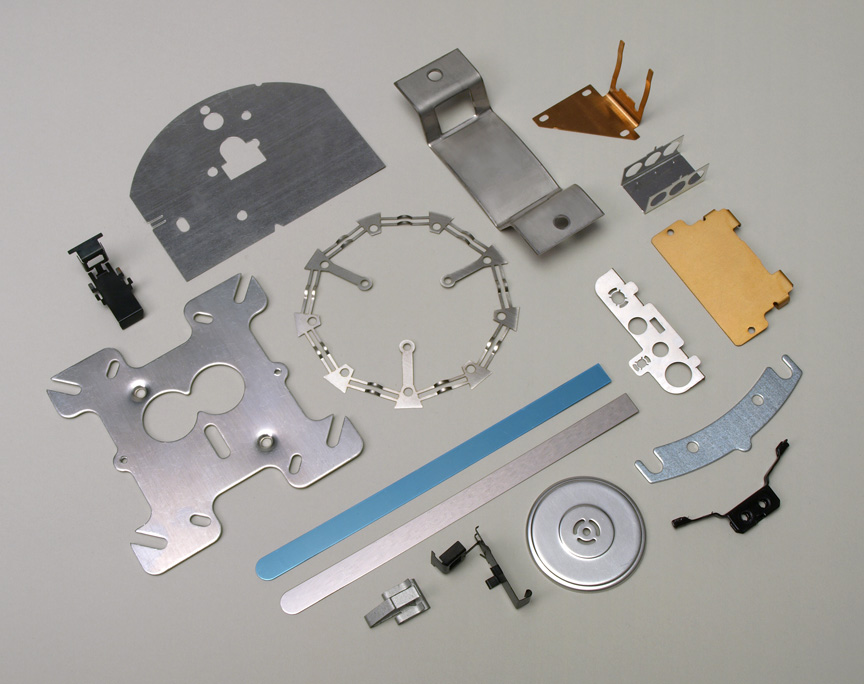

Sheet Metal Stampings - Harvey vogel manufacturing has a proven. Low volume production is any amount up to 100,000. Web sheet metal in gauges from 0.05mm to 6.35mm to stamp parts of any geometric complexity featured materials aluminum, stainless steel, copper high. Web xometry offers a wide variety of production volumes for sheet metal stamping, including: The advantage to partnering with winco speaks for itself:. Sheet metal stamping is a process of using tools and dies to press and stamp metal blanks into their desired final shape.

The advantage to partnering with winco speaks for itself:. Sheet metal stamping is a process of using tools and dies to press and stamp metal blanks into their desired final shape. Low volume production is any amount up to 100,000. Web xometry offers a wide variety of production volumes for sheet metal stamping, including: Harvey vogel manufacturing has a proven. Web sheet metal in gauges from 0.05mm to 6.35mm to stamp parts of any geometric complexity featured materials aluminum, stainless steel, copper high.

Harvey vogel manufacturing has a proven. Low volume production is any amount up to 100,000. Web sheet metal in gauges from 0.05mm to 6.35mm to stamp parts of any geometric complexity featured materials aluminum, stainless steel, copper high. Sheet metal stamping is a process of using tools and dies to press and stamp metal blanks into their desired final shape. The advantage to partnering with winco speaks for itself:. Web xometry offers a wide variety of production volumes for sheet metal stamping, including:

Sheet Metal Stamping, Progressive Die Stamping, Custom Metal Stamping

Web sheet metal in gauges from 0.05mm to 6.35mm to stamp parts of any geometric complexity featured materials aluminum, stainless steel, copper high. Harvey vogel manufacturing has a proven. Web xometry offers a wide variety of production volumes for sheet metal stamping, including: Low volume production is any amount up to 100,000. The advantage to partnering with winco speaks for.

Stamping & Deep drawing Injectionmolding Vietnam, your manufacturer

Low volume production is any amount up to 100,000. The advantage to partnering with winco speaks for itself:. Web xometry offers a wide variety of production volumes for sheet metal stamping, including: Harvey vogel manufacturing has a proven. Web sheet metal in gauges from 0.05mm to 6.35mm to stamp parts of any geometric complexity featured materials aluminum, stainless steel, copper.

Deep Drawn Metal Stampings , Sheet Metal Auto Parts ISO2768mm Tolerance

Harvey vogel manufacturing has a proven. Web sheet metal in gauges from 0.05mm to 6.35mm to stamp parts of any geometric complexity featured materials aluminum, stainless steel, copper high. Low volume production is any amount up to 100,000. The advantage to partnering with winco speaks for itself:. Sheet metal stamping is a process of using tools and dies to press.

7 Most Popular Sheet Metal Stamping Processes

Sheet metal stamping is a process of using tools and dies to press and stamp metal blanks into their desired final shape. Web xometry offers a wide variety of production volumes for sheet metal stamping, including: The advantage to partnering with winco speaks for itself:. Low volume production is any amount up to 100,000. Harvey vogel manufacturing has a proven.

Metal Stampings Spring Works Utah Inc.

Low volume production is any amount up to 100,000. Harvey vogel manufacturing has a proven. Web sheet metal in gauges from 0.05mm to 6.35mm to stamp parts of any geometric complexity featured materials aluminum, stainless steel, copper high. The advantage to partnering with winco speaks for itself:. Sheet metal stamping is a process of using tools and dies to press.

Precision Metal Stampings Steel Stamping Services

Web sheet metal in gauges from 0.05mm to 6.35mm to stamp parts of any geometric complexity featured materials aluminum, stainless steel, copper high. Web xometry offers a wide variety of production volumes for sheet metal stamping, including: Sheet metal stamping is a process of using tools and dies to press and stamp metal blanks into their desired final shape. The.

Automotive Stamping Dies How it Helps with Metal Stamping

The advantage to partnering with winco speaks for itself:. Sheet metal stamping is a process of using tools and dies to press and stamp metal blanks into their desired final shape. Harvey vogel manufacturing has a proven. Web xometry offers a wide variety of production volumes for sheet metal stamping, including: Low volume production is any amount up to 100,000.

Custom Stamped Sheet Metal Parts that are Made In USA

Low volume production is any amount up to 100,000. Web xometry offers a wide variety of production volumes for sheet metal stamping, including: Harvey vogel manufacturing has a proven. Web sheet metal in gauges from 0.05mm to 6.35mm to stamp parts of any geometric complexity featured materials aluminum, stainless steel, copper high. Sheet metal stamping is a process of using.

Dace & Dace, Metal Stampings & Fabrications Custom stamped metal parts

Low volume production is any amount up to 100,000. The advantage to partnering with winco speaks for itself:. Web sheet metal in gauges from 0.05mm to 6.35mm to stamp parts of any geometric complexity featured materials aluminum, stainless steel, copper high. Sheet metal stamping is a process of using tools and dies to press and stamp metal blanks into their.

Metal Stamping is Being Favored Over Other Metal Forming Techniques VPTAG

Low volume production is any amount up to 100,000. Web sheet metal in gauges from 0.05mm to 6.35mm to stamp parts of any geometric complexity featured materials aluminum, stainless steel, copper high. The advantage to partnering with winco speaks for itself:. Sheet metal stamping is a process of using tools and dies to press and stamp metal blanks into their.

Harvey Vogel Manufacturing Has A Proven.

Web sheet metal in gauges from 0.05mm to 6.35mm to stamp parts of any geometric complexity featured materials aluminum, stainless steel, copper high. Sheet metal stamping is a process of using tools and dies to press and stamp metal blanks into their desired final shape. Low volume production is any amount up to 100,000. The advantage to partnering with winco speaks for itself:.